Innovations in Underwater Welding for Marine Structures – Innovations in underwater welding for marine structures have revolutionized the way we construct, maintain, and repair underwater infrastructure.

Advanced technologies such as hyperbaric welding and remote operated vehicles (ROVs) have significantly enhanced safety and efficiency in underwater welding operations.

Friction stir welding (FSW) and laser welding techniques offer precise and reliable solutions for joining underwater materials with minimal heat input.

The development of specialized electrodes and fluxes has improved the mechanical properties and longevity of underwater welds.

These innovations not only address the challenges posed by underwater environments but also pave the way for sustainable and resilient marine structures in the future.

Innovations in Underwater Welding for Marine Structures

Innovations in underwater welding for marine structures have ushered in safer, more efficient, and technologically advanced methods, ensuring the integrity and longevity of underwater infrastructure.

Hyperbaric Welding

Hyperbaric welding stands out as a remarkable innovation in underwater welding technology, offering a controlled environment for dry welding operations beneath the sea’s surface.

Utilizing hyperbaric chambers, welders can work in pressurized conditions, mitigating the challenges posed by water pressure and environmental factors.

This method ensures enhanced safety for personnel, as it eliminates the need for divers to work in hazardous underwater conditions.

The controlled environment also facilitates higher precision and quality in welds, minimizing defects and ensuring structural integrity.

Hyperbaric welding has become indispensable in the construction and maintenance of marine structures, providing a reliable solution for joining metals underwater with optimal efficiency and safety.

Remote Operated Vehicles (ROVs)

Remote Operated Vehicles (ROVs) have revolutionized underwater welding by providing a sophisticated and efficient means of performing welding tasks in challenging underwater environments.

Equipped with advanced technology and precise maneuverability, ROVs can navigate intricate underwater structures with ease, reaching depths that are inaccessible or unsafe for human divers.

By integrating welding equipment onto ROVs, operators can remotely control welding operations from the surface, eliminating the need for divers and minimizing associated risks.

This not only enhances the safety of underwater welding projects but also allows for continuous monitoring and adjustment, ensuring optimal weld quality.

ROVs have become indispensable tools in the offshore industry, enabling efficient maintenance, repair, and construction of marine structures with unparalleled precision and reliability.

Friction Stir Welding (FSW)

Friction Stir Welding (FSW) represents a groundbreaking innovation in underwater welding, offering a solid-state joining technique that overcomes the limitations of traditional fusion welding methods.

This process involves the mechanical agitation of materials at the joint interface, generating frictional heat that softens the metal without melting it entirely.

As a result, FSW produces welds with minimal distortion, superior mechanical properties, and excellent fatigue resistance, making it particularly well-suited for joining aluminum and other high-strength alloys underwater.

Its ability to maintain structural integrity and produce high-quality welds without the need for consumable materials or shielding gases has made FSW a preferred choice for applications in marine structures, including shipbuilding, offshore platforms, and subsea pipelines.

Additionally, its environmentally friendly nature, low heat input, and reduced post-welding distortion contribute to its growing popularity as a reliable and efficient underwater welding solution.

Read Also: Top 5 Modern Forestry Equipment For Sustainable Logging

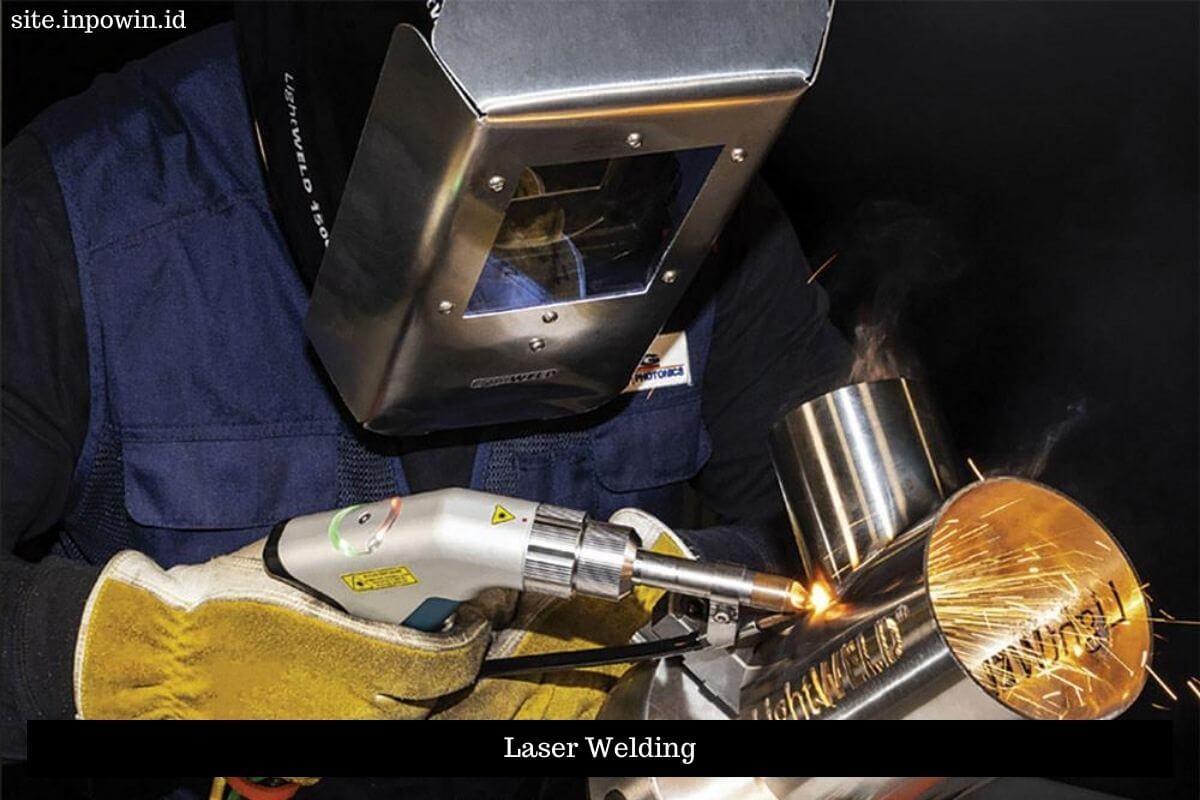

Laser Welding

Laser welding represents a cutting-edge advancement in underwater welding technology, offering precise and efficient joining of metals beneath the sea’s surface.

By utilizing a highly focused laser beam, this technique generates intense heat, allowing for rapid and localized melting of the materials to be welded.

Laser welding offers several advantages for underwater applications, including its ability to produce narrow and deep welds with minimal heat input, reducing the risk of distortion and thermal damage to surrounding areas.

Moreover, its non-contact nature eliminates the need for physical contact between the welding apparatus and the workpiece, minimizing the risk of contamination and ensuring a clean and precise weld seam.

Despite challenges related to beam propagation and underwater visibility, ongoing research and development efforts are continuously improving the feasibility and effectiveness of laser welding in marine environments.

As a result, laser welding holds promise as a versatile and efficient solution for a wide range of underwater welding applications, from ship repair to offshore construction projects.

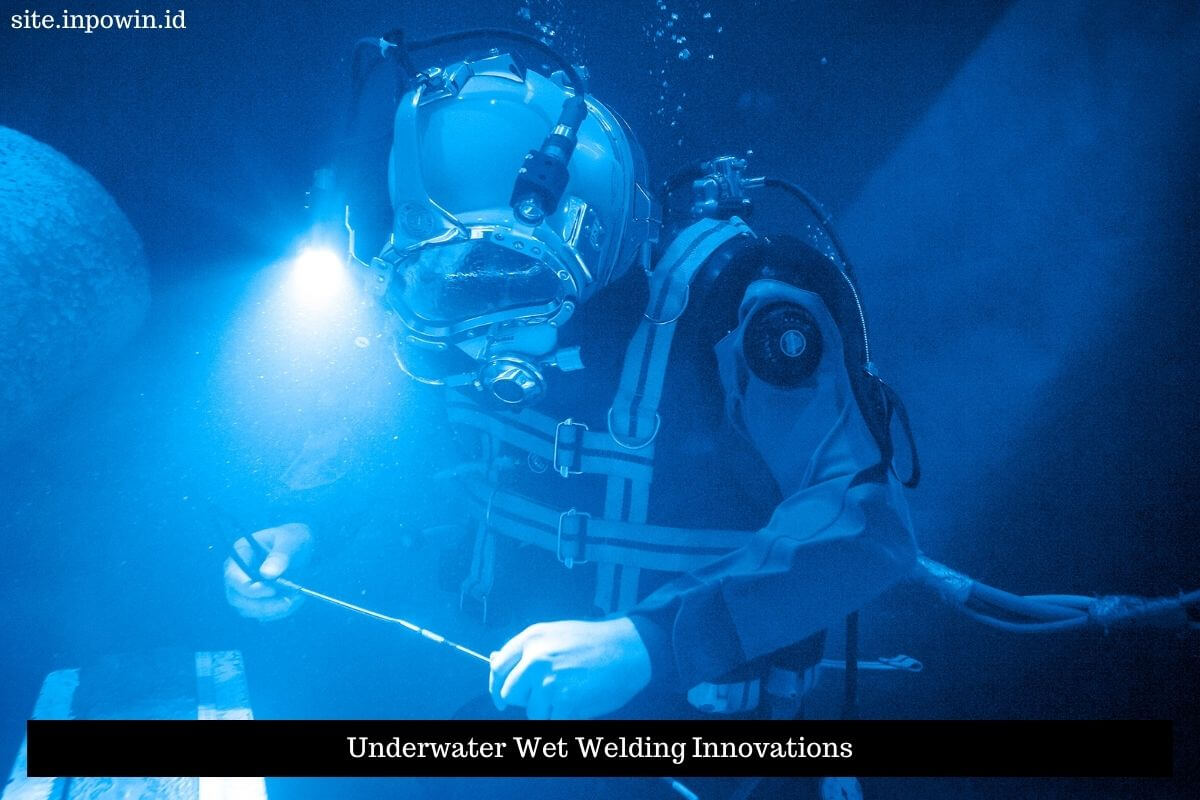

Underwater Wet Welding Innovations

Underwater wet welding innovations have significantly advanced the field of underwater welding, providing efficient and effective solutions for joining metals in submerged conditions.

Through the development of advanced electrodes and fluxes, underwater wet welding techniques have seen improvements in arc stability, control, and overall weld quality.

These innovations have resulted in welds with enhanced mechanical properties, including improved strength and corrosion resistance, essential for ensuring the integrity and longevity of marine structures.

Additionally, advancements in equipment design and diver training have contributed to safer and more reliable underwater wet welding operations.

As a result, underwater wet welding continues to be a preferred method for repairing and maintaining offshore structures, pipelines, and ships, playing a crucial role in sustaining the integrity of underwater infrastructure worldwide.

Electroslag Welding (ESW)

Electroslag welding (ESW) stands out as a notable innovation in underwater welding technology, offering a high deposition rate and efficient means of joining thick steel plates in submerged conditions.

This process involves the creation of a molten slag layer that shields the weld pool, allowing for deep penetration and the formation of strong, uniform welds.

ESW’s ability to accommodate thick materials makes it particularly suitable for the construction and repair of large marine structures such as offshore platforms and ship hulls.

Despite challenges associated with underwater application and slag removal, ongoing research and development efforts are continuously improving the feasibility and effectiveness of ESW in marine environments.

As a result, ESW remains a reliable and efficient solution for underwater welding projects, contributing to the safety, integrity, and longevity of marine structures worldwide.

Read Also: Applications In Underground Utility Installations

Conclusion

In conclusion, the continual advancements in underwater welding technology have revolutionized the marine engineering industry, ensuring the safety, integrity, and longevity of marine structures worldwide.

From the traditional methods of wet and dry welding to cutting-edge innovations such as hyperbaric welding, remote operated vehicles (ROVs), friction stir welding (FSW), laser welding, underwater wet welding, and electroslag welding (ESW), a diverse range of techniques now exists to address the unique challenges of welding in submerged conditions.

These innovations have not only enhanced the efficiency and precision of underwater welding operations but have also significantly reduced risks to human divers and minimized environmental impact.

As we look towards the future, continued collaboration between industry stakeholders, researchers, and regulatory bodies will be essential to drive further advancements in underwater welding technology, ensuring the sustainability and resilience of marine structures in the face of evolving challenges and demands.