Emerging Trends in 3D Printing Technology – As technology progresses, 3D printing is gaining popularity and significance.

This cutting-edge technology has made remarkable advancements recently, and as we move forward into 2023, numerous intriguing trends are emerging in the realm of 3D printing.

These encompass the adoption of novel materials, sophisticated software, and the expansion of 3D printing into various industries, presenting boundless opportunities.

In this article, we will delve into the prominent trends in 3D printing anticipated to influence the industry in 2023 and beyond.

Whether you’re a business proprietor, a designer, or simply an enthusiast, these trends warrant attention as they have the potential to revolutionize manufacturing and design methodologies.

Top 10 Emerging Trends in 3D Printing Technology in 2024

Here are our forecasts for 3D printing and digital manufacturing in 2024:

Automated assembly is poised for success within factory settings

The manufacturing sector is on the brink of a major transformation with the increasing prevalence of automated assembly technology.

Through the incorporation of multi-part assemblies, which include a mix of 3D printed metal and plastic components, industries stand to gain from the convenience offered by 3D printing services.

While the development of a single printer capable of seamlessly producing both metal and plastic parts is still pending due to challenges like varying processing temperatures, the concept of an automated assembly system facilitating simultaneous production of parts in both materials is gaining momentum.

The advantages of this technology will extend widely, particularly within the automotive industry.

It will enable 3D printing firms to integrate metals into plastic parts, fabricate wear-resistant and electricity-collecting components, apply surface treatments, and even embed conductors or motors into plastic parts.

This groundbreaking technology is poised to transform the manufacturing landscape, offering boundless opportunities for businesses and consumers alike.

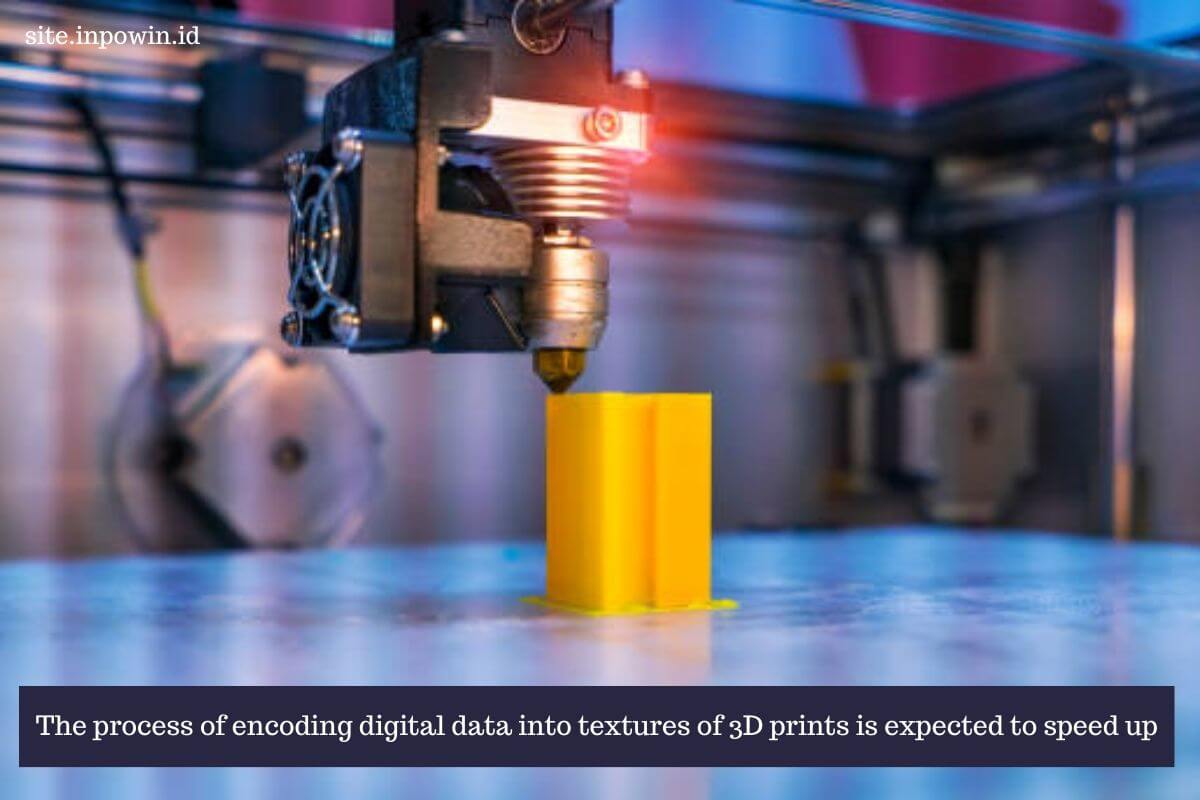

The process of encoding digital data into textures of 3D prints is expected to speed up

In the realm of 3D printing, enterprises are poised to access a new dimension of data storage and monitoring through advanced 3D printing solutions.

By integrating digital information into the texture of parts, businesses can capture a significantly larger data payload beyond just serial numbers, unlocking numerous possibilities for tracking and identification.

Through strategic embedding of this information into surface textures, both humans and machines can interpret it based on the shape or arrangement of surface features, enabling parts to be tagged overtly or covertly.

This proves particularly beneficial in scenarios where numerous serial numbers need to be printed across a part’s surface, allowing for both concealment and universal visibility.

As the importance of tracking parts and managing data systems grows, this trend is expected to continue expanding, fundamentally changing the way businesses handle and monitor their products.

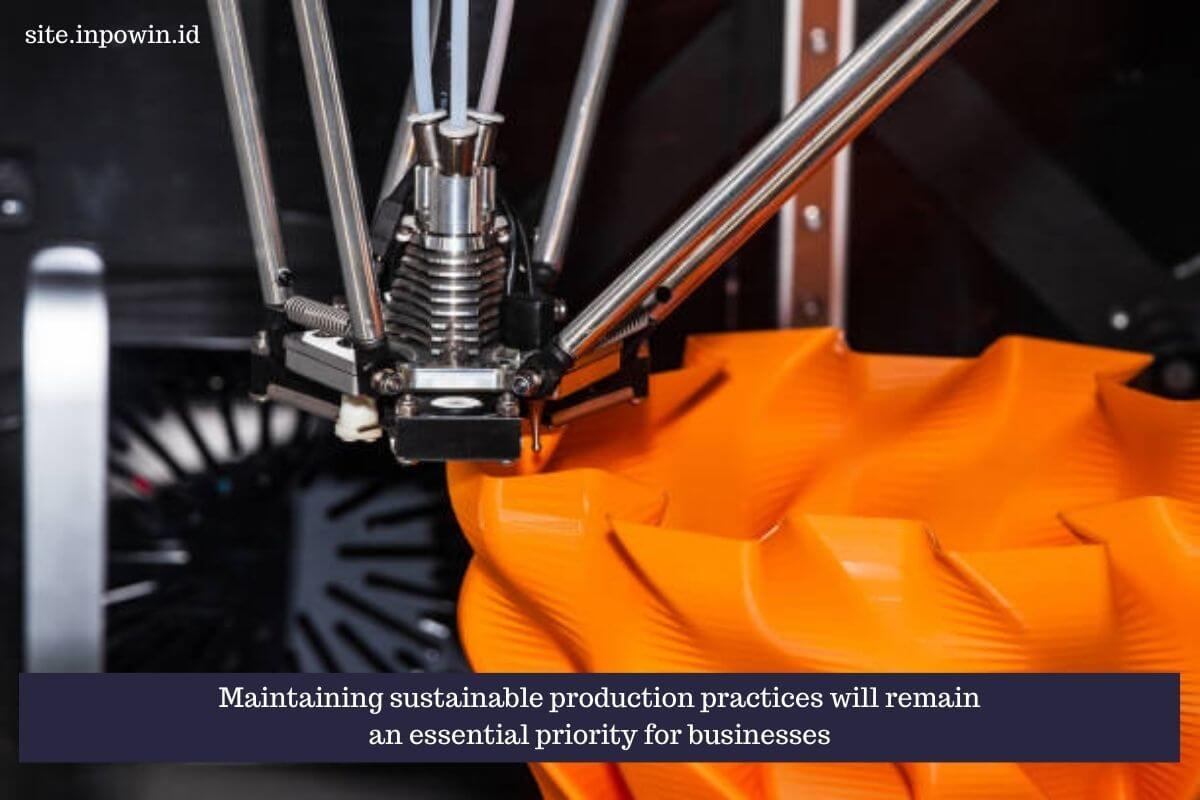

Maintaining sustainable production practices will remain an essential priority for businesses

The manufacturing sector has faced longstanding criticism for its disregard for environmental concerns.

Conventional manufacturing methods have historically prioritized output over sustainability, resulting in substantial carbon emissions and waste generation.

However, with the convergence of industrial 3D printing and manufacturing, there arises optimism for a more environmentally conscious future.

The advent of online 3D printing services in India is poised to transform the industry, offering businesses the ability to minimize waste, inventory, and CO2 emissions.

Through a reevaluation of design practices across the product lifecycle, engineers and designers can optimize material usage and reduce waste by consolidating parts and employing intricate geometries to create lightweight components.

In countries such as India, the adoption of 3D printing services is facilitating the production of lighter vehicles and aircraft, thereby enhancing fuel efficiency while mitigating greenhouse gas emissions and energy consumption.

As an increasing number of manufacturers utilize digital file transmission for local production rather than shipping finished goods, significant reductions in shipping-related costs, energy usage, waste, and emissions are anticipated.

The integration of 3D printing services into manufacturing processes is poised to chart a path towards a more sustainable future for the industry and the planet as a whole.

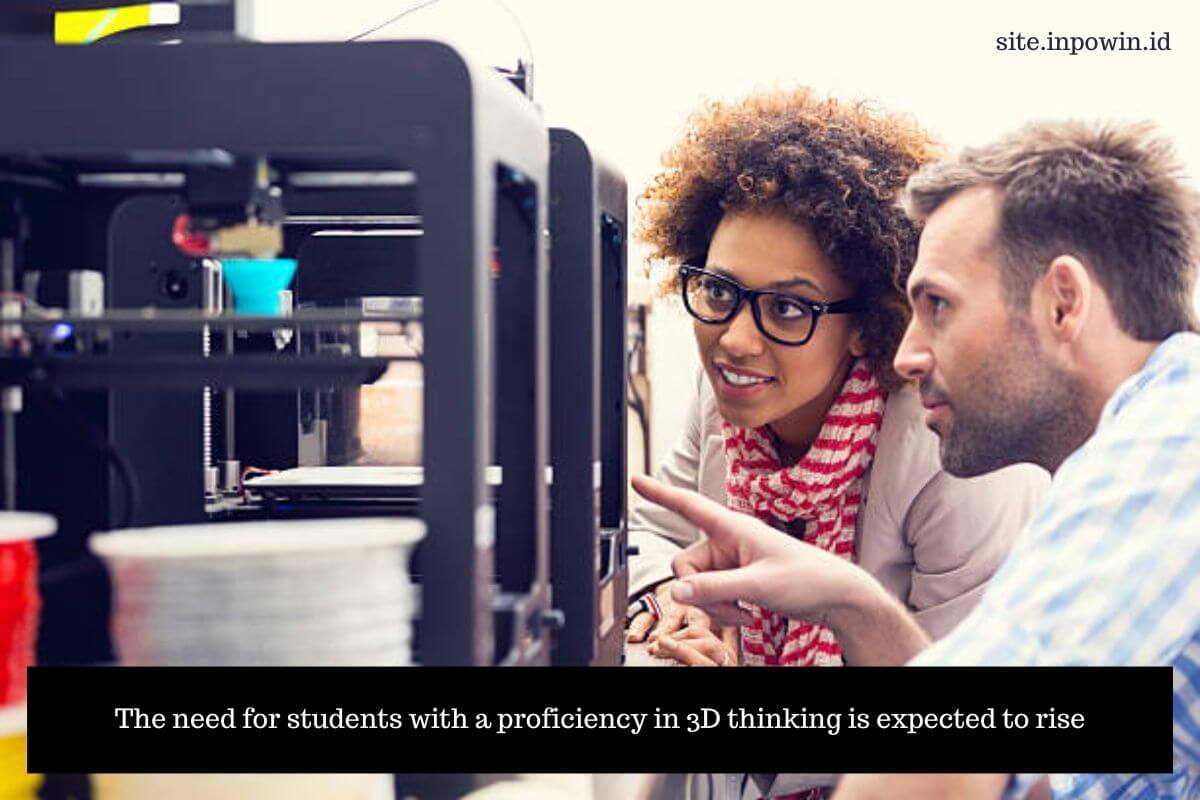

The need for students with a proficiency in 3D thinking is expected to rise

Higher education institutions are at a pivotal moment, contending with shifting demographics, heightened competition for enrollment, and the imperative to adequately equip students for the future workforce.

To address these challenges, a fundamental shift in mindset is imperative to adapt to the era of Industry 4.0.

Universities and educational programs must transcend conventional teaching methods and cultivate a fresh mindset that frees students from outdated perspectives, enabling them to harness future technologies such as online 3D printing and digital manufacturing.

Through the integration of cutting-edge software design tools, the implementation of progressive curricula focusing on 3D printing, and the introduction of new additive manufacturing degree programs, educators will furnish students with the necessary skills to capitalize on the multitude of job opportunities projected to emerge in the 3D printing industry over the next decade.

With these innovative educational initiatives in place, the upcoming generation of graduates will be well-positioned to excel in the swiftly evolving landscape of Industry 4.0.

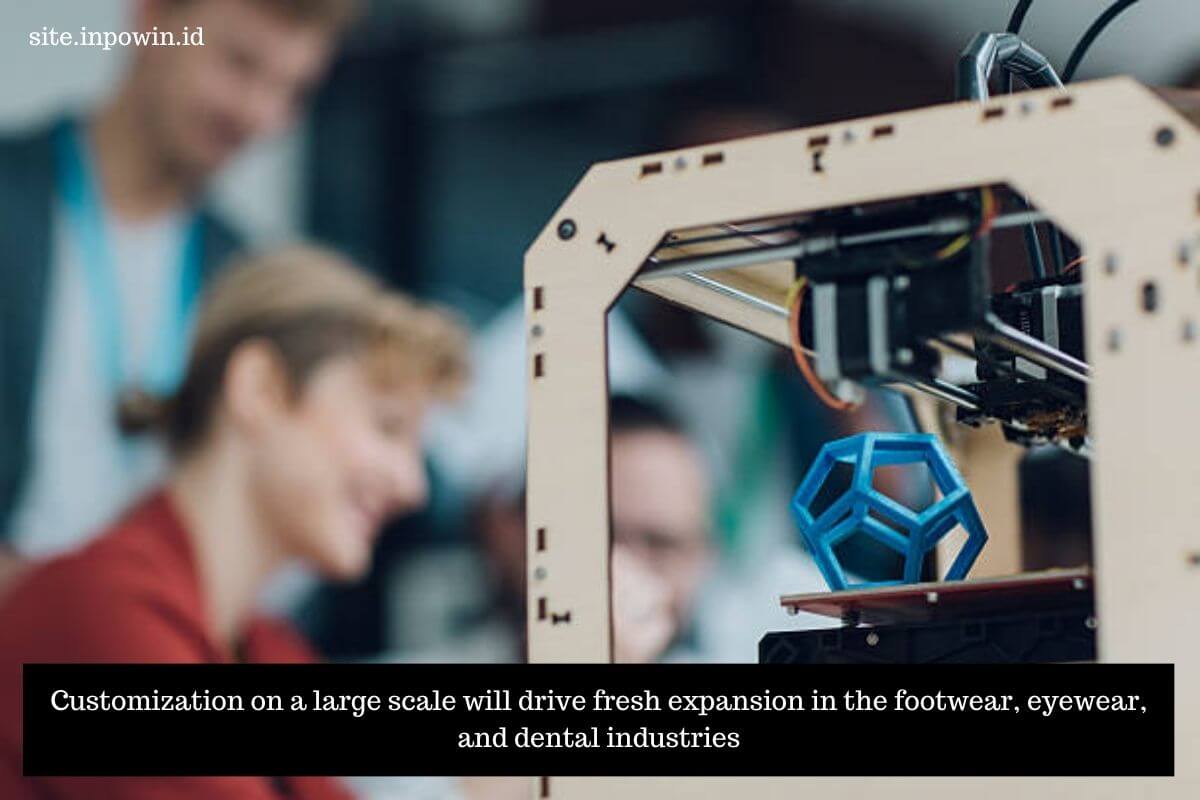

Customization on a large scale will drive fresh expansion in the footwear, eyewear, and dental industries

The consumer health industry is set to experience substantial growth and uptake of digital manufacturing technologies, particularly as sectors like footwear, eyewear, and orthodontics rapidly integrate 3D printing.

Moreover, the customizable nature of 3D printing in Bangalore makes it an appealing choice for orthodontic and eyewear applications.

With these industries increasingly relying on 3D printing services to fulfill the need for personalized, top-tier products, the momentum of the digital manufacturing revolution will only accelerate.

Conclusion

To sum up, 3D printing is swiftly progressing and innovating across diverse sectors, spanning healthcare, automotive, and consumer goods.

There’s a notable transition within the industry, moving from prototype creation to final production, with an emphasis on enhancing part excellence and broadening material selections.

Progress in software development and data handling is enhancing system administration and the potential for large-scale customization.

As we approach 2023, the possibilities of 3D printing technology appear boundless, with fresh applications and practical scenarios unfolding continuously.